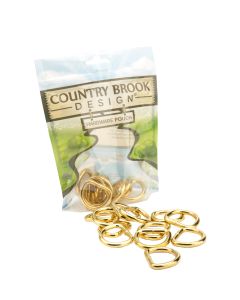

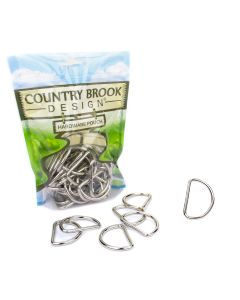

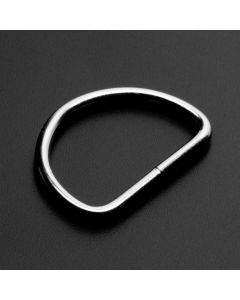

Metal D-Rings

-

2 Inch Welded D-RingsOut of stock

2 Inch Welded D-RingsOut of stock

Metal D-Rings

D-Rings are the most common type of webbing rings, and have numerous applications across a wide variety of industries.

We offer D-Rings in nickel plated steel, brass, and stainless steel. Use welded D-rings for maximum strength and die cast D-rings for light duty applications.

Here's a sample list of common items that use D-rings:

- Luggage

- Handbags

- Pet Collars

- Tow-Straps

- Buoyancy

- Compensator

- Camera Straps Belts