Polypropylene Webbing

Polypropylene Webbing

Polypropylene webbing, or "polypro," is a popular strapping material for two reasons: it is economical and it can be used in many of the same applications as nylon. Polypro is flexible, water-proof, and lightweight with tensile strengths between 600-1000 pounds, depending on the width and the manufacturer.

You can use polypro webbing for new projects or to repair existing items used in or around water, e.g., life jackets, boat rigging, tent straps and tie downs, and more. It is also great for belts, luggage straps, and light duty straps.

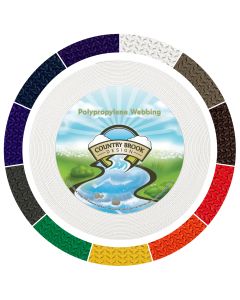

It comes in a wide variety of standard colors, including popular neon colors which increase visibility in low light conditions.

Unique advantages of polypro over nylon webbing:

- Stretch resistant so it retains its shape

- Water-proof quality makes it useful for projects exposed to water and humidity

- Doesn't absorb water which means it will float

- More resistant to acid, alkaline, oil and grease than nylon webbing

Carol's Tip: Whether you say ravel or unravel, it can afflict any unfinished project. With Country Brook Design® binding and our free instructional, you'll revel in non-raveling!