Understanding Dye Sublimation: A Guide for Small Startup Businesses

In the rapidly evolving world of digital printing, dye sublimation emerges as a standout method for producing high-quality, vibrant prints on a variety of materials. For small startup businesses looking to delve into the lucrative realm of customized products, understanding and mastering dye sublimation can be a game changer. This easy, step-by-step guide will introduce you to the basics of dye sublimation and discuss the necessary equipment, materials, and strategies to effectively utilize this technology to elevate your business.

What is Dye Sublimation?

Dye sublimation is a digital printing technique that uses heat and pressure to transfer dye onto materials such as fabric, plastic, and ceramics. Unlike other printing methods, dye sublimation is rooted in deep science. Let's take a look at the principles behind this extraordinary process.

Dye sublimation is a digital printing technique that uses heat and pressure to transfer dye onto materials such as fabric, plastic, and ceramics. Unlike other printing methods, dye sublimation is rooted in deep science. Let's take a look at the principles behind this extraordinary process.

The Science Behind It

Dye sublimation relies on the thermodynamic properties of sublimation dyes, which have the capability to sublimate—that is, transition from the solid phase directly to the gaseous phase under specific temperature and pressure conditions, without passing through a liquid phase. This process is governed by the principles of thermodynamics and kinetics.

Dye sublimation relies on the thermodynamic properties of sublimation dyes, which have the capability to sublimate—that is, transition from the solid phase directly to the gaseous phase under specific temperature and pressure conditions, without passing through a liquid phase. This process is governed by the principles of thermodynamics and kinetics.

The dyes used in sublimation printing are selected based on their ability to sublime efficiently at controlled temperatures (usually between 350°F and 400°F). These dyes typically consist of dispersed dyes which are finely ground to enhance their sublimation characteristics. Upon heating, the molecular bonds holding the dye in solid form weaken, allowing the dye molecules to enter the gas phase.

Sublimation ink is composed of the sublimation dye dispersed in a liquid solvent, often glycol. This solvent serves to transport the dye onto the sublimation paper and evaporates during the heat press stage. The volatility of the solvent is critical—it must evaporate without leaving residues that could affect the material’s texture or the clarity of the image.

The substrate material plays a critical role. For effective sublimation printing, the substrate must contain polymers, such as polyester, which possess open molecular structures that can trap the dye gas when heated. During the sublimation process, the heated dye gas expands and penetrates the open polymer structure of the substrate. As the substrate cools, the polymers close, encapsulating the dye within the material’s fibers. This encapsulation at the molecular level is what gives sublimated products their durability and colorfastness.

The substrate material plays a critical role. For effective sublimation printing, the substrate must contain polymers, such as polyester, which possess open molecular structures that can trap the dye gas when heated. During the sublimation process, the heated dye gas expands and penetrates the open polymer structure of the substrate. As the substrate cools, the polymers close, encapsulating the dye within the material’s fibers. This encapsulation at the molecular level is what gives sublimated products their durability and colorfastness.

A heat press applies controlled heat and pressure to ensure uniform sublimation. The temperature must be high enough to sublime the dye but not so high as to damage the substrate. The pressure is necessary to ensure close contact between the paper and the substrate, facilitating the transfer of the dye gas into the material.

Once the dye is within the substrate and the heat source is removed, the dye molecules cool and revert to their solid state, now permanently part of the substrate. This change is irreversible, making the dye part of the substrate’s structure and rendering the image resistant to typical forms of wear and degradation, such as washing or friction.

Benefits of Dye Sublimation

- Durability: The prints are less susceptible to fading and distortion over time.

- Quality: Produces high-quality prints with vibrant and sharp colors.

- Versatility: Suitable for printing on a wide range of materials.

- Cost-Effective: While initial setup costs might be high, the cost per unit is competitive for bulk orders.

Starting a Dye Sublimation Business

Step 1: Understanding Your Market

Before diving into dye sublimation, it's crucial to identify your target market. It's not enough to say you're going to make money doing sublimation. What are you sublimating? Who are you sublimating it for? Why do they want it? Whether it's customized apparel, promotional items, or decorative products, knowing your customers’ needs helps tailor your products effectively. Take the time to really sit and think about who you're going to sell to.

Step 2: Essential Equipment and Materials

- Sublimation Printer: Invest in a reliable printer designed specifically for sublimation printing. These printers use sublimation inks, which are essential for the process. Here's a list of some tried and true players in the sublimation printer market:

- Sublimation Ink: This is a specialized type of ink used specifically in the dye sublimation printing process. Unlike regular inks that lay on top of a substrate, sublimation ink is designed to bond directly with the material at a molecular level. This ink is unique because it transitions from a solid directly to a gas when heated, bypassing the liquid state through a process known as sublimation. Pay special attention to getting the correct ink for your particular printer: Some printers will only work with specific ink cartridges.

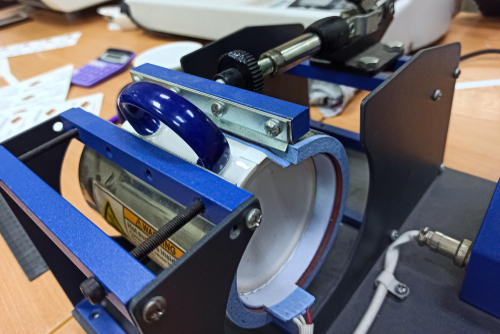

- Heat Press: Transfers the dye onto the material. The type of press depends on the products you plan to make (e.g., flat for t-shirts, cylindrical for mugs). It's essential to get a quality heat press. A cheap press might not heat your product evenly, causing quality control issues, frustration, and wasted materials.

- Sublimation Paper: Sublimation paper is a specialized type of transfer paper used in dye sublimation printing, which is integral to transferring images onto various substrates. The unique composition of sublimation paper includes a coating that optimizes the release of ink when heated. This coating is crucial because it regulates the release of the ink’s gas during the sublimation process, ensuring that the colors are transferred efficiently and with high fidelity to the original design. The paper itself is typically lightweight yet robust enough to handle the intense heat required to initiate the sublimation process, which usually ranges between 350-400 degrees Fahrenheit.

- Products to Sublimate On: There are countless niche products that can be sublimated onto:

- Apparel: This includes t-shirts, hoodies, jerseys, leggings, and socks. Apparel items must be made of polyester or a high-polyester blend to ensure the dye adheres properly.

- Mugs and Drinkware: Ceramic mugs, stainless steel tumblers, and plastic drinking bottles are popular choices. These items need a special polymer coating to accept the sublimation ink.

- Home Decor: Items like pillowcases, blankets, curtains, and rugs can be sublimated. These require a high percentage of polyester fabric to work well with the sublimation process.

- Accessories: This category includes items like tote bags, face masks, hats, and scarves. Like apparel, these items should have a high polyester content for effective sublimation.

- Hard Goods: You can sublimate onto rigid products like smartphone cases, keychains, clocks, and coasters, provided they are coated with a special polymer layer that can absorb the sublimation dye.

- Signage and Displays: Sublimation is ideal for creating flags, banners, signs, and backdrops. These items are typically made from polyester fabric or have a polyester coating suitable for sublimation.

- Photographic Panels and Art: Metal sheets (commonly aluminum), specially coated for sublimation, are used to create vibrant photographic prints and artwork.

- Personalized Gifts: These can include items like puzzles, mouse pads, jewelry, and Christmas ornaments. They require a polymer coating to ensure that the sublimation ink transfers correctly and lasts long.

Step 3: Setting Up Your Workspace

Setting up an efficient workspace is key to smooth operation. Ensure you have ample space for your printer, heat press, and storage for materials and finished products. Ventilation is also important, as the sublimation process can produce fumes.

Step 4: Time to Sublimate!

- Create or Obtain Design: You can create your designs or use customer-provided images.

- Print the Design: Use your sublimation printer to print the design onto sublimation paper using sublimation inks.

- Heat Pressing: Place the printed paper on the substrate and use a heat press to transfer the image. Temperature and pressure settings are crucial and vary depending on the material.

Step 5: Be Seen aka Marketing

Effective marketing strategies can make or break your new business. Utilize online platforms such as social media, your business website, and local advertising. Showcasing your unique offerings with high-quality images and engaging content can attract more customers.

Challenges and Solutions

Quality Control

Maintaining consistent quality can be challenging. Regular testing and calibration of equipment are essential to ensure product quality remains high. In particular, it's quite easy for the nozzles on your sublimation printer to become clogged. Before starting a job, I always perform a nozzle check. This simply prints easy to see, single lines of ink to determine of all of your nozzles are firing. If one or more lines are missing from your nozzle check, that means you have a clogged nozzle. Run the head cleaning routine on your printer to clear the clog and get things working again.

Supply Chain Management

As a startup, managing inventory and supply chains can be daunting. Establish reliable supplier relationships and keep track of your inventory to avoid shortages or excesses. Don't be afraid to shop around for new vendors if you have quality control problems. I once had to replace a long-time sublimation paper vendor because I kept getting wrinkled paper that was cut wrong. It was extra work, but once I found a vendor I liked, the quality of my prints improved, and I had happier customers.

As a startup, managing inventory and supply chains can be daunting. Establish reliable supplier relationships and keep track of your inventory to avoid shortages or excesses. Don't be afraid to shop around for new vendors if you have quality control problems. I once had to replace a long-time sublimation paper vendor because I kept getting wrinkled paper that was cut wrong. It was extra work, but once I found a vendor I liked, the quality of my prints improved, and I had happier customers.

Customer Education

Educating your customers about the benefits and unique aspects of sublimated products can help in boosting sales and customer satisfaction.

Conclusion

Dye sublimation offers a fantastic opportunity for startups to enter the vibrant world of customized products. With its ability to produce durable, high-quality prints and its versatility across a range of materials, mastering dye sublimation can set your business apart in the competitive market. By investing in the right equipment, understanding your market, and employing effective marketing strategies, your startup can not only succeed but thrive in the exciting world of dye sublimation.

For further learning and to stay updated on the latest trends in dye sublimation, continue engaging with industry news, attending workshops, and networking with other professionals in the field. Your journey in dye sublimation is just beginning, and the possibilities are endless!

Review and Win! Share your verified review and get a chance to win a $25 store credit!

Review and Win! Share your verified review and get a chance to win a $25 store credit!